PrimaVera Project

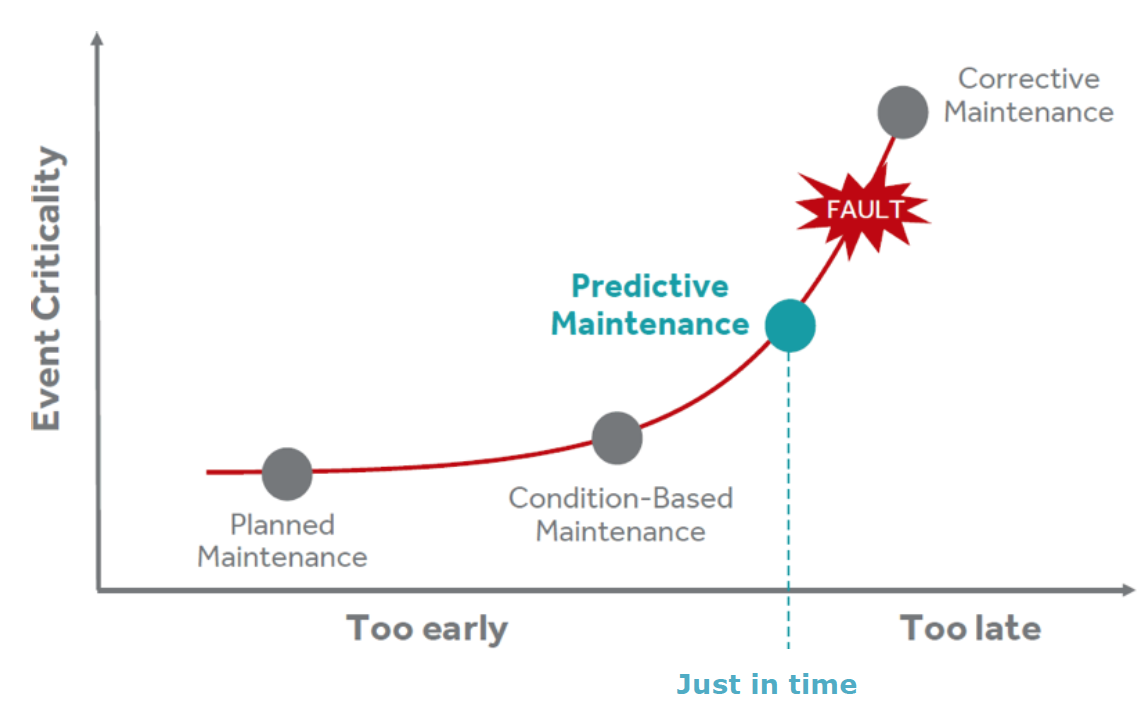

No more train delays, power outages, or failure of production machines? The PrimaVera project, funded by the Dutch National Research Agenda (NWA), represents a major step towards this goal. With predictive maintenance, or just-in-time maintenance (maintenance just before a system breaks down), the reliability of infrastructure and production resources can be increased and the costs of maintenance can be reduced.

Existing predictive maintenance techniques only work for small-scale systems and are difficult to scale up. Choices made in one place in the chain have an important influence on other processes in the chain. The choice of a certain type of sensors and measurements influences the type of predictions that can be made, and therefore also the quality of the predictions. That is why cross-level optimization methods are being developed within PrimaVera.

2026 |

| : From Sinterklaas to Smart Maintenance Organizational Enablers. In: Work in progress, 2026. |

| : The Knowledge Product Catalogue as a Tool to Support Dissemination in Inter-Organizational Research Projects. In: Work in progress, 2026. |

2025 |

| : Quantifying the suitability and feasibility of predictive maintenance approaches. In: Computers & industrial engineering, vol. 194, iss. 110342, 2025. |

| : Large Scale Asset Detection Within Railway Scene Point Cloud Data From Mobile Laser Scanning. In: IEEE Access, 2025, ISSN: 2169-3536. |

| : Preparing for predictive maintenance: Employee perspectives on job demands and resources before and after its implementation. In: Applied Ergonomics, vol. 129, pp. 104561, 2025. |