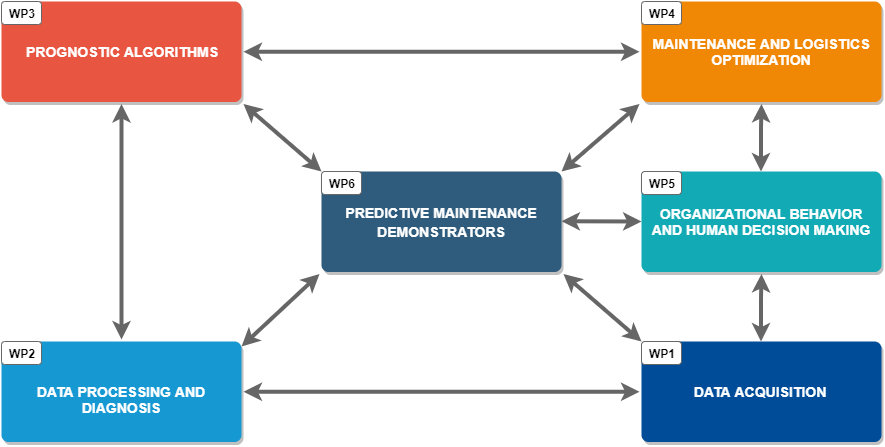

The Project Organization

The PrimaVera project is structured in six technical work packages and two concerning dissemination and management. The chain wide communication and management are considered crucial components in this project. The consortium contains 13 partners: 6 academic partners, and 10 industrial or societal partners.

WP1 | Data Acquisition

Goal

Discover the knowledge and the information in the data by

- determining what to measure and how to measure it so as to optimize the quality of the collected data for the purpose of PM;

- investigating novel sources of data and information collection;

- creating a decision support system.

Involved members

- Bram Ton (Saxion Hogeschool)

WP2 | Data Processing and Diagnosis

Goal

The main goal of WP2 is the transfer of raw sensor data into actionable information relevant for maintenance. WP2 will develop novel automated methods for real-time data validation and correction, building upon probabilistic and statistical techniques for missing value imputation and outlier detection. These methods will take care to exclude effects of changing operational conditions on the measurements and isolate these from the effects caused by failures.

Involved members

- Dr. Rul Castro (TU Eindhoven)

- Alexander Mey (TU Eindhoven)

- Roel Bouman (Radboud University)

WP3 | Prognostic Algorithms

Goal

The goal of WP3 is to develop scalable and accurate prognostics, i.e. algorithms to predict the future failure behaviour of components and systems. WP3 will quantify relevant key performance indicators, such as the remaining useful life (RUL), time to first failure, availability, and reliability, etc. Thus, WP3 turns the diagnostic information developed in WP2 into useful indicators needed by WP4 to take optimal maintenance decisions.

Involved members

- Lisandro A. Jimenez Roa (University of Twente)

- Luc Keizers (University of Twente)

- Núbia Silveira (University of Twente)

- Natalia Ribeiro Marinho (University of Twente)

- Thom Badings (Radboud University)

WP4 | MAINTENANCE AND LOGISTICS OPTIMIZATION

Goal

The goal of WP4 is to develop accurate, efficient, effective, and robust methods for large-scale maintenance optimization and simultaneous service logistics control. The novelty of the suggested maintenance plans lies in 1) the incorporation of the key performance indicators (developed in WP3); 2) the combination of maintenance and service logistics planning; and 3) the adaptability and robustness of the underlying algorithms.

Involved members

- Dr. Stella Kapodistria (TU Eindhoven)

- Ragnar Eggertsson (TU Eindhoven)

- Mattias Volk (University of Twente)

- Zhao Kang (TU Eindhoven)

- Ahmadreza Marandi (TU Eindhoven)

WP5 | ORGANIZATIONAL BEHAVIOR AND HUMAN DECISION MAKING

Goal

The goal of WP5 is to develop a fundamental understanding of the user requirements and design principles for developing effective decision support tools in the domain of predictive maintenance. These insights will be used to design novel, user-centered maintenance tools that make the user-system interaction more effective and efficient. In a similar vein, developing advanced maintenance techniques is useless unless they are well-integrated into the organization’s overall business processes. As such, WP5 will develop new procedures for the effective implementation of data-driven maintenance systems within organizations.

Involved members

- Bas van Oudenhoven (TU Eindhoven)

WP6 | PREDICTIVE MAINTENANCE DEMONSTRATORS

Goal

The consortium will build three demonstrators, integrating the knowledge, insights, methods and models developed in the WPs 1–5, each delivering a generic building block. Combining the building blocks will translate these into tangible tools that demonstrate the added value of the research to industrial applications, thereby providing a window for dissemination and exploitation.